Offset printing is still one of the most reliable and cost-effective methods for high-quality commercial printing. If you’re planning to buy an offset printing machine, one of the first things you need to understand is the types of offset printing machines available. Each type serves a different purpose and suits different business needs.

In this article, we’ll explain the major types of offset presses, how they work, their benefits, and what kind of jobs they’re best suited for.

1. Sheet-Fed Offset Printing Machines

What is Sheet-Fed Offset Printing Machines?

A sheet-fed offset printing machine prints on individual sheets of paper, rather than continuous rolls. These sheets are manually or automatically fed into the machine one at a time.

Key Features of Sheet-Fed Offset Printing Machines:

- Ideal for medium to high-quality print jobs

- Available in different sizes like 19×26″, 20×29″, and 28×40″

- Can print 1-color to 8-color jobs

- Precise registration and consistent quality

Best For:

- Brochures

- Catalogs

- Posters

- Packaging cartons

- Commercial marketing materials

Common Brands:

- Heidelberg SM/CD series

- Komori Lithrone series

- Mitsubishi Diamond series

Pros:

- High print quality

- More flexible with paper types and sizes

- Easy to change jobs frequently

Cons:

- Slower than web presses for high-volume jobs

- More expensive per unit for short runs

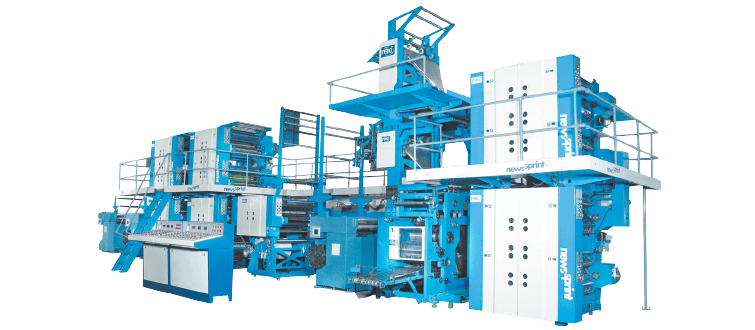

2. Web Offset Printing Machines

What is Web Offset Printing Machines?

Web offset machines print on large rolls (or “webs”) of paper, which are continuously fed into the press. The paper is cut and folded after printing.

There are two types of Web Offset Printing Machines: Coldset and Heatset.

- Coldset web offset: Used for newspapers and prints that don’t require drying

- Heatset web offset: Uses dryers to cure ink – ideal for glossy magazines, flyers

Key Features of Web Offset Printing Machines:

- Extremely fast printing – up to 70,000 copies per hour

- Can print both sides of the paper at once (perfecting units)

- Automated reel changers and folding units

Best For:

- Newspapers

- Magazines

- Books

- High-volume print jobs

Pros:

- High-speed production

- Lower cost per page for large print runs

- Suitable for continuous or repetitive jobs

Cons:

- Not suitable for short runs

- Expensive initial setup

- Requires more space and skilled operation

3. Mini Offset Printing Machines

What is Mini Offset Printing Machines?

Mini offset presses are compact versions of full-sized sheet-fed machines. They’re commonly used by small print shops or for job work printing.

Key Features of Mini Offset Printing Machines:

- Simple to operate

- Lower maintenance cost

- Typically single-color or two-color units

- Prints on small-size sheets (up to A3 or A2)

Best For:

- Letterheads

- Bill books

- Envelopes

- Wedding cards

- Short-run jobs

Pros:

- Very affordable

- Compact size – fits in smaller spaces

- Ideal for beginners or small businesses

Cons:

- Limited in size and colors

- Not suitable for large-volume or color-critical jobs

4. Perfecting Offset Machines (Both-Side Printing)

What is Perfecting Offset Machines?

Perfecting presses are a type of sheet-fed machine that can print on both sides of the sheet in a single pass. They are also known as “straight and perfecting” presses.

Key Features of Perfecting Offset Machines:

- Dual-side printing in one go

- Speeds up production

- Reduces paper handling errors

Best For:

- Book printing

- Magazine work

- Jobs that need duplex printing

Pros:

- Saves time

- Reduces production cost

- High registration accuracy

Cons:

- More complex machine setup

- Slightly higher cost than straight presses

5. UV Offset Printing Machines

What is UV Offset Printing Machines?

UV offset machines are equipped to handle UV inks and coatings. These inks are dried instantly using UV lamps, making them suitable for high-gloss or specialty printing.

Key Features of UV Offset Printing Machines:

- Uses UV curing instead of air drying

- Works on non-absorbent materials like plastic, PVC, or metallic boards

- Ideal for high-end print jobs

Best For:

- Packaging (e.g., cosmetics, pharma)

- Labels

- Luxury marketing materials

Pros:

- Sharp, vibrant colors

- Scratch-resistant finish

- Dries instantly – no waiting

Cons:

- Higher ink and maintenance cost

- Requires ventilation and cooling systems

Summary Table of Types Of Offset Printing Machines

| Type | Best For | Speed | Color Options | Suitable For |

|---|---|---|---|---|

| Sheet-Fed | Brochures, Catalogs | Medium | 1 to 8 color | Medium runs |

| Web Offset | Newspapers, Books | Very High | 1 to 4 color | High-volume |

| Mini Offset | Bill books, Cards, Letterheads | Low | 1 to 2 color | Small businesses |

| Perfecting Press | Duplex jobs, Books | High | 4 to 10 color | Book publishers |

| UV Offset | Premium packaging, Plastic jobs | Medium | 4 to 6 color | Niche industries |

Final Thoughts

Choosing the right type of offset printing machine depends on your business size, the kind of print jobs you do, and your budget. Sheet-fed and mini offset machines are ideal for small to medium businesses, while web offset is for bulk printing giants. UV presses open doors to niche, high-value jobs.

If you’re unsure which one suits your setup, we at Printoholic can guide you through your options based on your actual requirements. Contact us today for best deals.