If you’ve ever held a glossy magazine, a colorful brochure, or a high-quality poster in your hand, chances are it was produced using an offset printing machine. Offset printing is one of the most common and reliable printing methods used around the world.

Whether you’re a business owner, designer, or someone curious about printing technology, this article will help you understand what an offset printing machine is and how it works—explained in the simplest terms.

What is an Offset Printing Machine?

An offset printing machine is a type of commercial printing press that transfers ink from a plate to a rubber blanket and then onto the printing surface, usually paper. It is called “offset” because the ink is not directly applied to the paper—it’s offset through an intermediate step (the rubber blanket).

This method is commonly used for high-volume printing tasks like newspapers, magazines, books, brochures, catalogs, and packaging materials

Key Features of Offset Printing

Here are some features of offset printing machines.

- High-quality image reproduction

- Fast and efficient for large print runs

- Consistent color and image sharpness

- Cost-effective for bulk printing

- Supports a wide variety of paper types and finishes

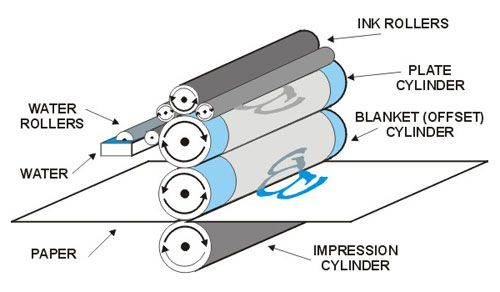

Main Components of an Offset Printing Machine (Explained Simply)

Understanding how an offset press works starts with knowing its basic parts. Here’s a breakdown of each component in beginner-friendly language:

1. Printing Plate

- What it is: A thin sheet of metal (usually aluminum) that contains the image or text to be printed.

- Function: The image area on the plate attracts ink, while the non-image areas repel it.

2. Plate Cylinder

- What it is: A rotating drum that holds the printing plate.

- Function: Transfers the inked image from the plate to the rubber blanket.

3. Blanket Cylinder

- What it is: A drum covered with a soft rubber blanket.

- Function: Receives the ink from the plate and “offsets” it onto the paper.

4. Impression Cylinder

- What it is: A metal roller that presses the paper against the blanket cylinder.

- Function: Ensures the image is firmly printed onto the paper.

5. Ink Rollers

- What it is: A system of rollers that supply ink to the printing plate.

- Function: Spreads ink evenly across the plate’s surface.

6. Dampening System

- What it is: A set of rollers that apply a water-based solution to the plate.

- Function: Keeps the non-image areas free from ink.

7. Paper Feed System

- What it is: A system that feeds sheets or rolls of paper into the press.

- Function: Moves the paper through the machine at high speed.

8. Delivery Unit

- What it is: The final section of the machine.

- Function: Collects the printed sheets in a neat stack.

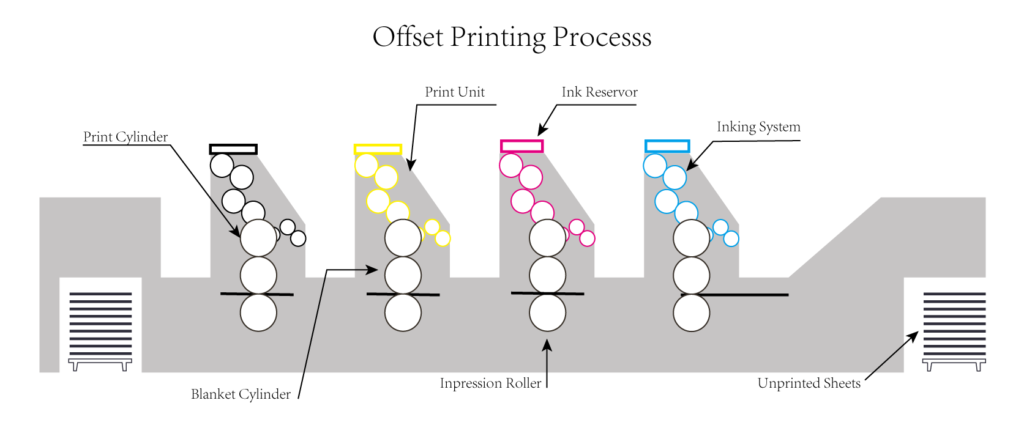

How Does an Offset Printing Machine Work? (Step-by-Step)

Let’s walk through the printing process step-by-step in plain language:

Step 1: Pre-press Setup

The design is created on a computer and transferred to a metal plate using a process called CTP (Computer-to-Plate). Separate plates are made for each ink color (CMYK: Cyan, Magenta, Yellow, Black).

Step 2: Plate Mounting

Each plate is mounted onto the plate cylinder of the press.

Step 3: Inking and Dampening

- The ink rollers apply ink to the plate.

- The dampening system applies a water solution to prevent non-image areas from getting ink.

Step 4: Image Transfer

- The inked image transfers from the plate to the rubber blanket.

- Then, the image is offset (transferred) from the blanket to the paper.

Step 5: Paper Feeding and Printing

- The paper feed system pushes the paper between the blanket and impression cylinder.

- The paper receives the printed image.

Step 6: Drying and Delivery

- The printed sheet is dried (with heat or air).

- It is then stacked in the delivery unit.

Types of Offset Printing Machines

There are two main types of offset printing presses:

1. Sheet-Fed Offset Printing Machine

- Prints on individual sheets of paper

- Ideal for brochures, posters, catalogs, and packaging

Here are some popular used offset printing machines in best conditions.

- HEIDELBERG SM 66-5P 1998

- HEIDELBERG SM 102-8P 2007

- HEIDELBERG CD 102-6 LYYL 2003

- HEIDELBERG SM 72V 1985

- HEIDELBERG SM 102 ZP CP TRONIC

- HEIDELBERG SM 72 ZP 1989

- HEIDELBERG MO-S 1985

2. Web Offset Printing Machine

- Prints on continuous rolls of paper

- Commonly used for newspapers, magazines, and books

Advantages of Using Offset Printing

Here are some advantages of using offset printing machines.

- Superior Print Quality: Sharp, clean images with rich colors

- Cost-Effective: Lower cost per page for large runs

- Versatile Media Options: Works on various paper types and finishes

- Fast Production Speeds: Suitable for high-volume commercial printing

When Should You Choose Offset Printing?

You should choose offset printing when:

- You need to print large quantities

- You require high-quality results

- You want to use special inks or finishes (like metallic or UV)

- You’re printing magazines, books, or business stationery

Explore Our Offset Printing machine Stocklist.

Frequently Asked Questions (FAQs)

Is offset printing better than digital printing?

For large runs, offset printing is more cost-effective and offers better quality. Digital printing is better for short runs and faster turnaround.

Can I print in full color with offset printing?

Yes! Most offset presses use CMYK color models to print full-color images.

How long does it take to set up an offset print job?

It usually takes longer to set up compared to digital printing due to plate creation and machine setup, but it’s much faster during actual printing.

Conclusion

Offset printing machines are the backbone of the commercial printing industry. With their ability to produce high-quality prints at lightning speed, they’re the go-to solution for businesses around the world. By understanding how these machines work, you can make smarter decisions for your printing needs—whether you’re printing flyers, books, or magazines.