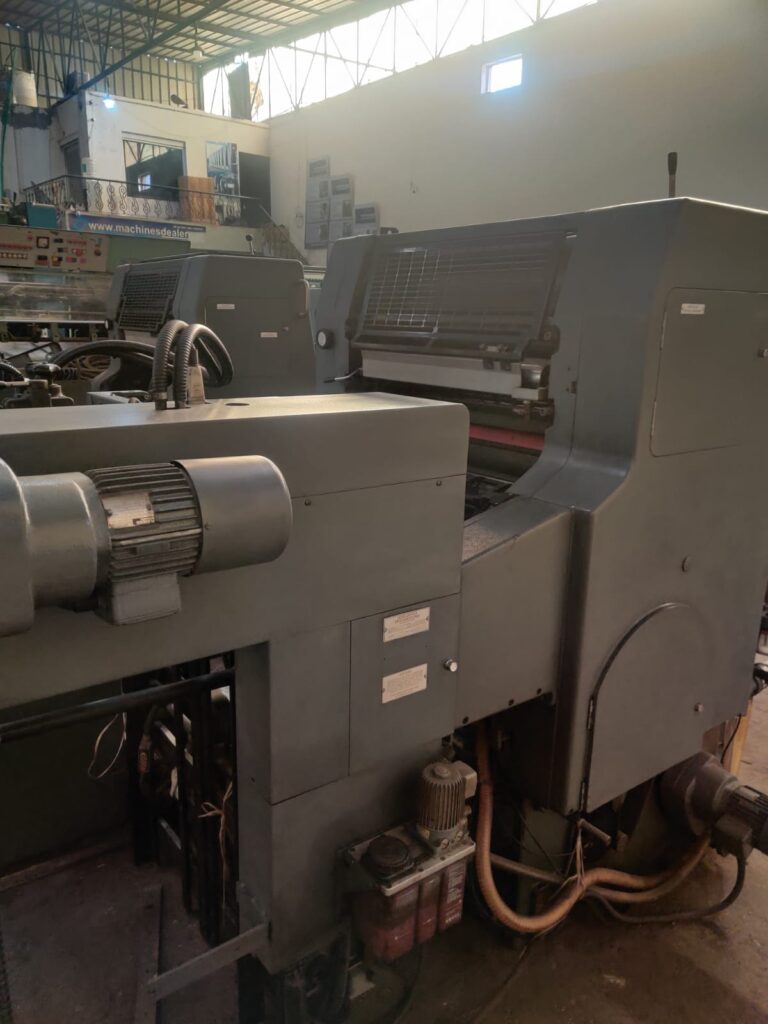

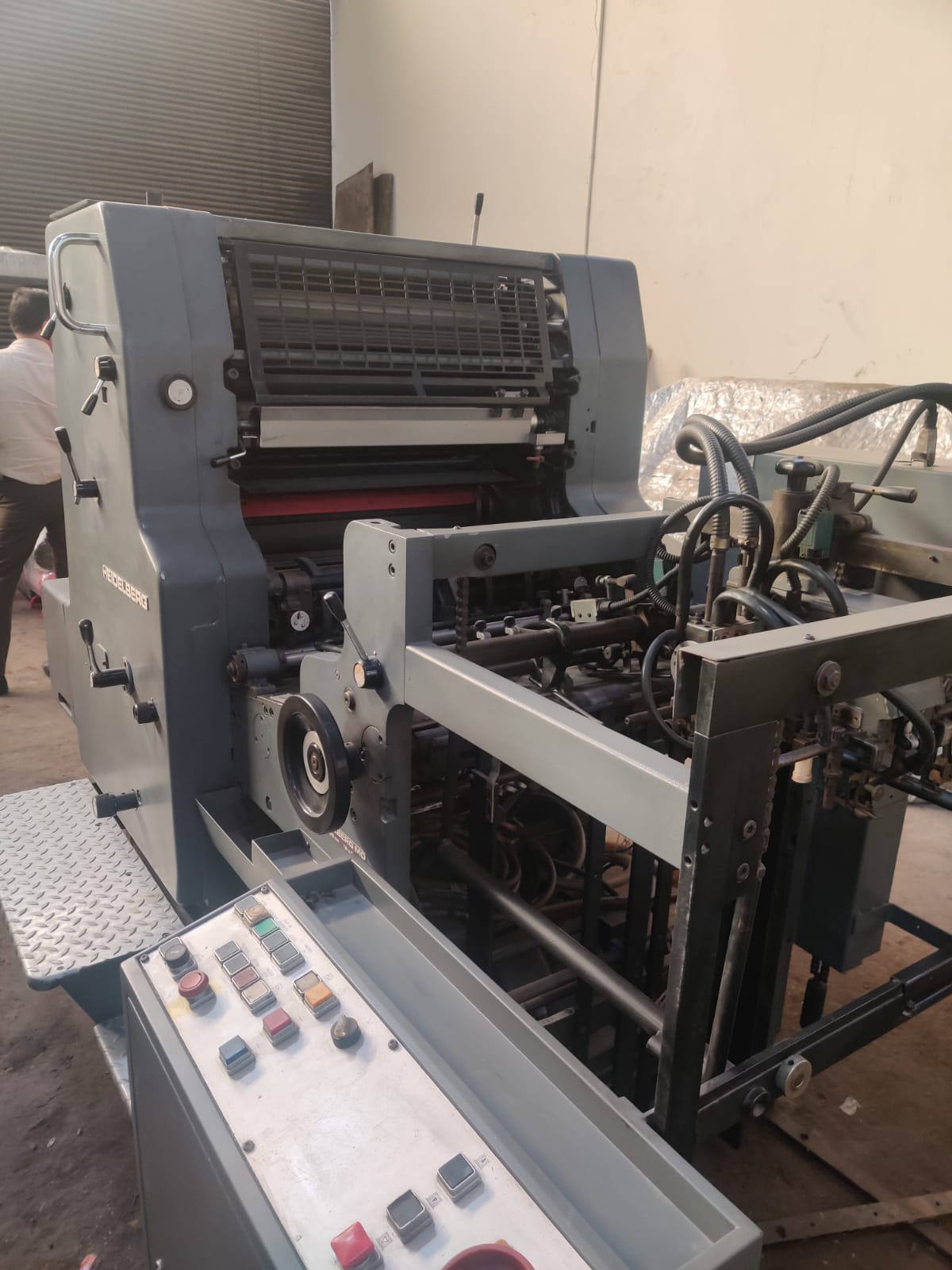

In the fast-paced world of commercial printing, one name continues to stand the test of time — Heidelberg. Known for its engineering precision and unbeatable reliability, Heidelberg presses have shaped the industry for decades. Among its legendary machines is the Used Heidelberg MO-S 1985, a durable and dependable offset printing press that’s still trusted by printers around the world.

This article discuss about what makes the MO-S special, its features, technical specifications, practical uses, and answers to common questions.

What Made the HEIDELBERG MO-S 1985 Stand Out?

The Used Heidelberg MO-S 1985 was built like a tank and designed to run non-stop. Here’s what made it a favorite among print shop owners:

- Stream Feeder System: This feature helped feed paper sheets smoothly and accurately, reducing jams and boosting productivity. It handled different types of paper with ease.

- A2+ Format Capability: With a sheet size of about 48 x 65 cm (19 x 25 inches), it was perfect for jobs like brochures, flyers, posters, and forms.

- Kompac III Dampening (Optional): Some models included this system for better control of ink and water balance, giving sharper images and more even color.

- Plus Version (N+P – Numbering and Perforating): Certain versions allowed for built-in numbering and perforating, perfect for printing tickets, invoices, and forms.

- Grafix Powder Sprayer: Prevented ink smudges by keeping freshly printed sheets from sticking to each other.

- Quick Plate Clamps: Made plate changes faster, helping printers save time during job setup.

- Built to Last: Heidelberg machines are famous for their long life, and the MO-S is no exception. Many are still running strong after millions of impressions.

Technical Specifications Of Heidelberg MO-S

Here are the key technical details most commonly seen in the HEIDELBERG MO-S 1985 for sale:

- Printing Units: Usually a 1-color press, but related MO models included 2, 4, or even 6-color versions.

- Max Sheet Size: 480 x 650 mm (around 19 x 25.5 inches)

- Min Sheet Size: About 210 x 280 mm

- Max Printing Area: 472 x 645 mm

- Speed: Up to 12,000 sheets per hour

- Paper Thickness: Can handle from thin paper (0.04 mm) to thicker stock (up to 0.6 mm)

- Feeder Type: Stream feeder for continuous sheet feeding

- Delivery: Most came with low pile delivery; high pile was available on some variants

- Weight: Around 2,950 kg for a single-color model

- Dimensions: Approx. 2.1 m (L) x 1.75 m (W) x 1.79 m (H)

Note: Specs may vary based on exact version or any upgrades.

Applications of Heidelberg MO-S 1985

The MO-S was made for versatility. Even with just one color, it could take on a wide range of jobs:

Commercial Printing:

- Flyers and brochures

- Business cards

- Letterheads and envelopes

- Booklet covers and inserts

Forms & Stationery:

- Invoices, receipts, and order forms

- Numbered tickets and vouchers

Short-Run Packaging:

- Folding carton prototypes

- Labels (on sheet-fed stock)

Specialty Projects:

- Calendars

- Small posters

Its ability to handle different paper types and deliver precise prints made it an all-rounder in small and medium-sized print shops.

Why Is the Heidelberg MO-S Still Valuable Today?

Despite being over 35 years old, the HEIDELBERG MO-S 1985 is still a smart choice for many printers. Here’s why:

- Trusted Heidelberg Quality: These machines were built to last. With proper care, they still produce clean, consistent prints.

- Budget-Friendly: A used MO-S costs a fraction of a modern press but still gets the job done for many printing needs.

- Simple Mechanics: Easier to maintain than today’s tech-heavy machines. Skilled operators can keep them running without needing advanced electronics.

- Reliable: Known for minimal downtime and strong performance over long runs.

Other Heidelberg Offset Printing Machines, You May Like

Here is the list of other most popular and high performance Heidelberg printing presses.

- HEIDELBERG SM 66-5P 1998

- HEIDELBERG SM 102-8P 2007

- HEIDELBERG CD 102-6 LYYL 2003

- HEIDELBERG SM 72V 1985

- HEIDELBERG SM 102 ZP CP TRONIC

- HEIDELBERG SM 72 ZP 1989

Frequently Asked Questions: HEIDELBERG MO-S 1985

What does the “S” in MO-S stand for?

The “S” means it has a stream feeder — a system that feeds sheets more continuously and precisely, boosting speed and accuracy.

Can this old machine still deliver high-quality prints?

Yes! With good maintenance and quality materials (plates, inks, paper), an MO-S can produce sharp, clear prints just like it did when new.

Are parts still available for the MO-S?

Yes, many dealers and independent technicians still carry parts or can source them. The MO series was popular, so support networks still exist.

What kind of daily maintenance does it need?

Clean the rollers, check the dampening system, lubricate key parts, and clear debris from the feeder and delivery. Regular checks prevent problems.

What are common add-ons or upgrades?

Many MO-S machines come with or are upgraded to:

1). Kompac III dampening system

2). Numbering and perforating units

3). Powder spray units

4). Refrigeration units for dampening control

Nice machine