In today’s fast-paced world, high-quality printing remains a cornerstone of industries ranging from publishing to packaging, advertising, and manufacturing. The art and science of achieving flawless prints fall under printing engineering, a multidisciplinary field that combines physics, chemistry, materials science, and advanced technology.

This article explores the intricate processes, technologies, and innovations driving printing engineering to deliver exceptional print quality.

What is Printing Engineering?

Printing engineering is the systematic study and application of techniques to produce high-quality printed materials. It encompasses the design, development, and optimization of printing processes, equipment, and materials to achieve precision, durability, and visual appeal. From traditional offset printing to modern digital and 3D printing, printing engineers ensure that every print meets stringent quality standards.

Key Components of Printing Engineering

- Substrate Selection: Choosing the right material (paper, plastic, metal, etc.) for the desired print outcome.

- Ink and Coating Chemistry: Formulating inks and coatings for vibrant colors, adhesion, and durability.

- Printing Technologies: Leveraging methods like offset, flexography, gravure, or digital printing for specific applications.

- Quality Control: Implementing rigorous testing to ensure color accuracy, resolution, and consistency.

The Science Behind High-Quality Prints

High-quality prints are the result of meticulous engineering and scientific principles. Below, we dive into the core elements that define printing excellence.

1. Color Management and Reproduction

Achieving accurate and vibrant colors is a hallmark of high-quality printing. Printing engineers rely on color management systems to maintain consistency across devices and substrates. This involves:

- Color Profiles: Using ICC (International Color Consortium) profiles to standardize color output.

- Spectrophotometry: Measuring color with precision instruments to ensure fidelity.

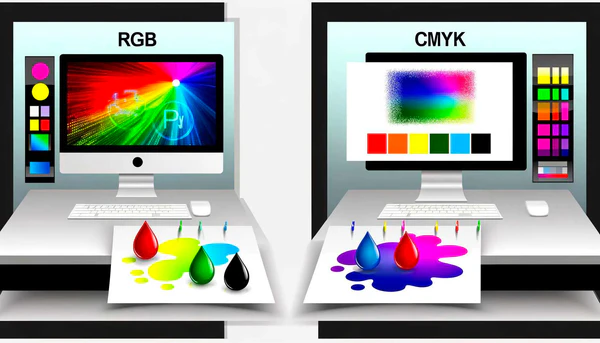

- CMYK vs. RGB: Converting digital RGB colors to CMYK for print, accounting for substrate and ink interactions.

By calibrating presses and monitors, engineers minimize color discrepancies, ensuring that the final print matches the designer’s vision.

2. Ink and Substrate Interactions

The choice of ink and substrate significantly impacts print quality. Printing engineers study the chemical and physical properties of inks and substrates to optimize adhesion, drying time, and durability. For example:

- Porous Substrates: Paper absorbs ink differently than non-porous materials like plastic or metal.

- Ink Formulations: UV-curable, water-based, or solvent-based inks are selected based on the printing method and substrate.

- Surface Tension: Engineers adjust ink viscosity and surface energy to prevent issues like smudging or poor adhesion.

Advanced coatings, such as varnishes or laminates, are often applied to enhance durability and aesthetic appeal.

3. Precision in Printing Technologies

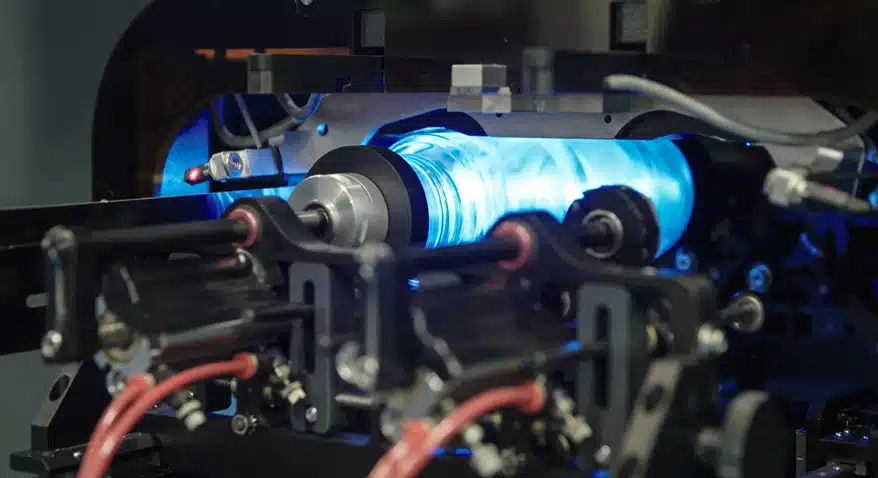

Different printing technologies offer unique advantages for specific applications. Printing engineers select and optimize these methods to achieve the desired outcome:

- Offset Printing: Ideal for high-volume runs, offering sharp images and consistent quality.

- Flexography: Commonly used for packaging, with flexible plates for uneven surfaces.

- Gravure: Delivers rich, continuous tones for high-quality magazines and catalogs.

- Digital Printing: Enables on-demand printing with variable data, perfect for personalized marketing.

- 3D Printing: Revolutionizing prototyping and manufacturing with layered material deposition.

Each method requires precise calibration of rollers, plates, or nozzles to ensure uniformity and clarity.

4. Resolution and Image Clarity

High-quality prints demand high resolution, measured in DPI (dots per inch). Printing engineers balance resolution with production efficiency:

- Screen Ruling: In offset printing, the number of lines per inch (LPI) affects image sharpness.

- Halftoning: Converting continuous-tone images into dot patterns for print reproduction.

- Anti-Aliasing: Smoothing jagged edges in digital prints for cleaner lines.

Modern presses use computer-to-plate (CTP) systems to enhance precision, reducing errors during plate creation.

5. Quality Control and Testing

To maintain high standards, printing engineers employ rigorous quality control measures:

- Densitometry: Measuring ink density to ensure consistent coverage.

- Proofing: Creating test prints to verify color and alignment before full production.

- Environmental Controls: Regulating temperature and humidity to prevent paper distortion or ink issues.

Automated inspection systems, equipped with cameras and sensors, detect defects in real-time, minimizing waste and ensuring consistency.

Innovations in Printing Engineering

The printing industry is evolving rapidly, driven by technological advancements and sustainability demands. Key innovations include:

1. Sustainable Printing Practices

Printing engineers are developing eco-friendly solutions to reduce environmental impact:

- Soy-Based Inks: Replacing petroleum-based inks with biodegradable alternatives.

- Recycled Substrates: Using post-consumer recycled paper and plastics.

- Energy-Efficient Presses: Modern presses consume less power and produce less waste.

2. Smart Printing Technologies

The integration of IoT (Internet of Things) and AI is transforming printing:

- Predictive Maintenance: Sensors monitor press performance to prevent downtime.

- Automated Workflows: AI optimizes print settings for efficiency and quality.

- Variable Data Printing: Personalizing prints for targeted marketing campaigns.

3. 3D and Functional Printing

Beyond traditional 2D prints, printing engineering is pushing boundaries with:

- 3D Printing: Creating complex structures for medical, aerospace, and automotive industries.

- Functional Printing: Producing printed electronics, such as flexible circuits and sensors.

These advancements are expanding the scope of printing engineering into new frontiers.

Challenges in Printing Engineering

Despite its advancements, printing engineering faces several challenges:

- Cost vs. Quality: Balancing high-quality output with budget constraints.

- Material Variability: Substrates and inks can vary between batches, affecting consistency.

- Environmental Regulations: Complying with strict laws on emissions and waste.

- Technological Adaptation: Keeping pace with rapid innovations requires continuous learning.

Printing engineers address these challenges through research, collaboration, and investment in cutting-edge solutions.

Why Printing Engineering Matters

High-quality prints are more than just visually appealing—they convey professionalism, enhance brand identity, and drive customer engagement. Whether it’s a vibrant magazine, a durable product label, or a precision-engineered 3D prototype, printing engineering ensures that every detail is perfect. By blending science, technology, and creativity, printing engineers play a vital role in industries worldwide.

Conclusion

Printing engineering is the backbone of high-quality print production, combining scientific precision with innovative technology. From color management to substrate selection, every aspect is meticulously optimized to deliver flawless results. As the industry embraces sustainability and smart technologies, printing engineering continues to evolve, shaping the future of print media and beyond.

For businesses and individuals seeking top-tier printing solutions, understanding the science behind printing engineering can unlock new possibilities. Whether you’re producing marketing materials, packaging, or cutting-edge 3D prints, partnering with skilled printing engineers ensures exceptional quality and lasting impact.